JOINT LIGHT TACTICAL VEHICLES

JLTV

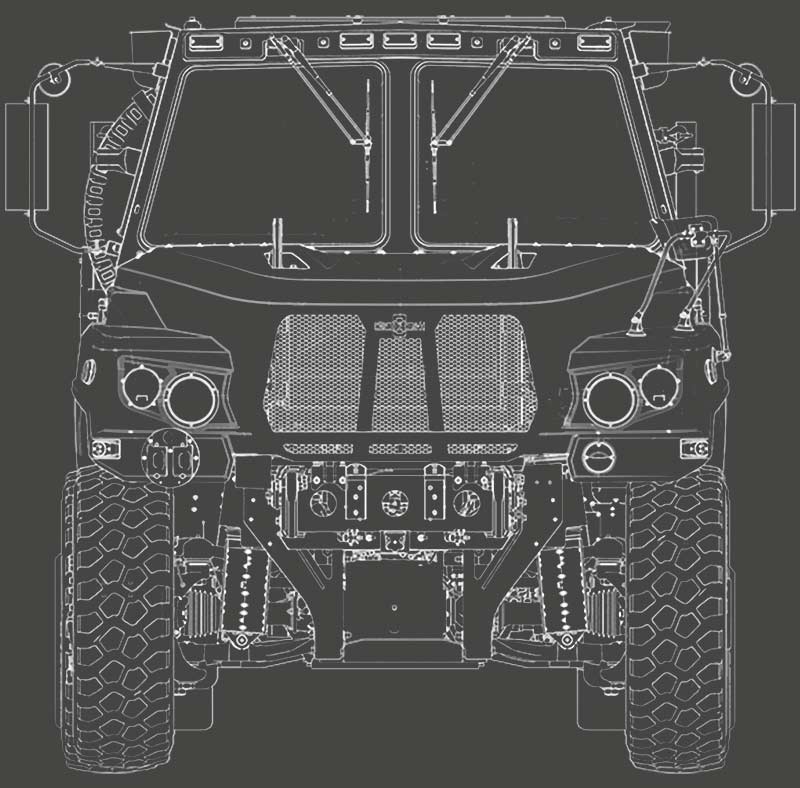

The Oshkosh® Defense JLTV has consistently demonstrated its ability to fill critical capability gaps for U.S. and international militaries. The patented TAK-4iTM intelligent independent suspension system, scalable levels of protection, and complete plug-and-play C4ISR capability showcase the technology and engineering excellence at Oshkosh Defense.

The Oshkosh JLTV is the go-anywhere, do-anything light tactical vehicle.

INNOVATION. EXPERTISE. PERFORMANCE.

BUILT IN TODAY’S WORLD, DESIGNED FOR TOMORROW’S

Since 2015, Oshkosh Defense has provided the United States military and allied foreign governments with over 22,000 JLTVs. Designed to improve performance, payload, and protection capabilities, Oshkosh Defense’s JLTV is the go-to vehicle when mobility is critical, and performance is paramount.

Oshkosh’s JLTV variants and trailers can fill mission needs across a full spectrum of military operations.

SEE PHOTOS OF OSHKOSH’S JLTV & eJLTV

Oshkosh Defense’s JLTV has undergone extensive testing and evaluation to make sure it’s mission-ready.

The JLTV features unprecedented performance needed for harsh battlefield environments.

The JLTV’s comprehensive protection system is designed to bring more soldiers home safe and sound.

Oshkosh’s JLTV can be paired with various Aftermarket kits to evolve as missions change.

Oshkosh Defense JLTV-EXP

ADVANCEd technolgoy and SAFETY for MISSION SUCCESS

UNMATCHED MOBILITY CAPABILITIES

Featuring unprecedented performance with the patented TAK-4i™ intelligent independent suspension system, the Oshkosh JLTV quickly adjusts to achieve diverse transportability needs. It can be transported by air (CH-47 and CH-53 helicopters’ C-130, C-5, C-17 and A400 Cargo fixed-wing aircraft), land and sea.

It’s ready on arrival, giving troops the reliability and performance needed for harsh battlefield environments.

JLTV Mobility Features:

- 20 in. (50.8 cm.) wheel travel

- 70% faster off-road performance

- Helicopter transportable

- Fixed-wing aircraft transportable

- Amphibious transportable

COMPREHENSIVE PROTECTION SYSTEM

The JLTV achieves the level of protected mobility required to improve survivability in missions today and tomorrow with scalable crew protection installed or removed in the field.

JLTV Protection Features:

- Patented blast-protected seats

- Automatic fire protection system

- Proven scalable crew protection system

VEHICLE SYSTEMS & TECHNOLOGIES

Purpose-built with plug-and-play access for the complete range of modern battlefield technologies and aftermarket kits, the JLTV keeps forces connected. And it’s easy to upgrade as technologies and missions evolve.

JLTV Technology Features:

- Fully integrated C4ISR capabilities

- 5,100 lbs. (2313 kg.) payload (2-door)

- 3,500 lbs. (1587.5 kg.) payload (4-door)

ADVANCEd technolgoy and SAFETY for MISSION SUCCESS

UNMATCHED MOBILITY CAPABILITIES

Featuring unprecedented performance with the patented TAK-4i™ intelligent independent suspension system, the Oshkosh JLTV quickly adjusts to achieve diverse transportability needs. It can be transported by air (CH-47 and CH-53 helicopters’ C-130, C-5, C-17 and A400 Cargo fixed-wing aircraft), land and sea.

It’s ready on arrival, giving troops the reliability and performance needed for harsh battlefield environments.

JLTV Mobility Features:

- 20 in. (50.8 cm.) wheel travel

- 70% faster off-road performance

- Helicopter transportable

- Fixed-wing aircraft transportable

- Amphibious transportable

COMPREHENSIVE PROTECTION SYSTEM

The JLTV achieves the level of protected mobility required to improve survivability in missions today and tomorrow with scalable crew protection installed or removed in the field.

JLTV Protection Features:

- Patented blast-protected seats

- Automatic fire protection system

- Proven scalable crew protection system

VEHICLE SYSTEMS & TECHNOLOGIES

Purpose-built with plug-and-play access for the complete range of modern battlefield technologies and aftermarket kits, the JLTV keeps forces connected. And it’s easy to upgrade as technologies and missions evolve.

JLTV Technology Features:

- Fully integrated C4ISR capabilities

- 5,100 lbs. (2313 kg.) payload (2-door)

- 3,500 lbs. (1587.5 kg.) payload (4-door)

PATENTS AND APPLICATIONS ON THE JLTV FAMILY OF VEHICLES AND RELATED TECHNOLOGIES

There are more than 100 different mission package configurations for the Oshkosh Defense JLTV General Purpose (GP) platform. This is the only light tactical vehicle that is as adaptable and able to accept additional armor without sacrificing mobility or transportability.

Heavy Guns Carrier (HGC)

The Oshkosh Defense® JLTV Heavy Guns Carrier (HGC) can pack a lethal punch. This vehicle is designed for crew-served and remote weapon systems.

With a protected gun mount, the JLTV HGC is the principal light vehicle for over-watch and direct fire support of infantry maneuvers, convoy escort, and security missions.

Advanced non-kinetic weapon systems (such as lasers) can also be integrated to defend against swarming drones and other unmanned aerial vehicle (UAV) threats.

Heavy Guns Carrier (HGC) Features

The JLTV HGC Features:

- TAK-4iTM intelligent independent suspension

- Scalable protection

- Plug-and-play C4ISR capability

I WOULD LIKE TO THANK YOU FOR THE LIFE OF MY SON. HE WAS INVOLVED IN A LIVE FIRE TRAINING INCIDENT AND YOUR ARMORED VEHICLE ENSURED HE AND HIS TEAMMATES WERE ABLE TO EVACUATE SAFELY AND UNINJURED. ALL THEIR ISSUED AND PERSONAL ITEMS ARE REPLACEABLE, BUT THEIR LIVES AND HEALTH ARE NOT.

Grateful Father and Master Sergeant, U.S. Air Force